SS Bucket Elevator

SS Bucket Elevator Specification

- Structure

- Conveyor System

- Elevating Speed

- Up to 70 m/min

- Belt Size

- Custom as per elevator model

- Rolling Speed

- Variable 0.2 to 1.2 m/s

- Frame Material

- Stainless Steel (SS304/SS316 options)

- Dimension (L*W*H)

- Flexible - Customized as per site requirement

- Bucket Volume

- 2 to 18 Liters (depends on model)

- Belt Type

- Rubber/PU/SS chain belt

- Material

- Stainless Steel

- Load Capacity

- up to 2 Tons/hr (customizable)

- Lifting Height

- up to 25 meters (customized as per requirement)

- Cycle Time

- Varies with configuration

- Size

- Customized

- Weight

- Depends on size and configuration

- Power

- 1.5 to 7.5 kW (depending on capacity and height)

- Voltage

- 380V/415V, 3 Phase

- Working Temperature

- Up to 180C

- Application

- Material Handling

- Drive Type

- Electric Motor with Gearbox

- Number of Buckets

- Customized as per requirement

- Discharge Type

- Automatic/Manual discharge option

- Noise Level

- <75 dB

- Lubrication System

- Centralized lubrication available

- Installation Type

- Vertical or Inclined

- Bucket Material

- Stainless Steel SS304/SS316

- Feed Inlet

- Designed as per input material

- Surface Finish

- Polished/Matte

- Maintenance

- Low; Easy access for cleaning and inspection

SS Bucket Elevator Trade Information

- Minimum Order Quantity

- 1 Unit

- Delivery Time

- 30 Days

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Middle East, Central America, Asia, Western Europe, Africa

- Main Domestic Market

- All India

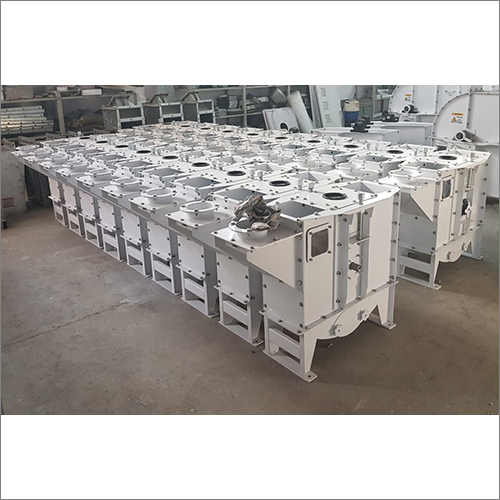

About SS Bucket Elevator

Bucket Elevator is designed for handling bulk materials and specializes in lifting large amounts of those materials up into the air and through the system. We are engaged in providing our clients with a wide array of Bucket elevators that are manufactured using high-quality raw materials. Bucket Elevator comes with a ribbed crone pulley for self cantering and avoiding slippage. Its gear motor is coupled directly with the drive pulley shaft.

Customizable Design for Diverse Applications

Each SS Bucket Elevator is tailored to specific site and material requirements, offering flexibility in bucket size, belt type, elevator dimensions, and load capacity. Whether you need vertical or inclined installation, the design ensures optimal performance for a wide range of industries, including food, pharmaceuticals, and chemicals.

Efficient Operation and Minimal Maintenance

Equipped with a centralized lubrication system and easy-to-access components for cleaning and inspection, this elevator minimizes downtime and maintenance costs. The electric drive, variable rolling speed, and adjustable discharge modes allow seamless integration into existing workflows, improving material transfer rates and operational reliability.

Superior Material Quality and Finish

Manufactured from high-grade stainless steel SS304 or SS316, this bucket elevator offers excellent corrosion resistance and durability, even at working temperatures up to 180C. The choice of polished or matte finishes supports hygiene and aesthetic preferences, while the robust construction ensures a long service life in demanding conditions.

FAQs of SS Bucket Elevator:

Q: How is the SS Bucket Elevator adapted for different material handling requirements?

A: The SS Bucket Elevator is customized for each project, including the number and volume of buckets, belt type, feed inlet size, and overall dimensions, to suit the specific input material and site conditions. This flexibility enables reliable handling of various bulk products with efficient discharge mechanisms.Q: What are the primary benefits of using stainless steel (SS304/SS316) for the buckets and frame?

A: Stainless steel SS304/SS316 provides superior corrosion resistance, strength, and hygiene, making the elevator suitable for food, pharmaceutical, and chemical applications. It also ensures longevity and consistent performance even at elevated temperatures up to 180C.Q: When should I opt for automatic or manual discharge in my bucket elevator system?

A: Automatic discharge is ideal for continuous operations where materials must be processed with minimal interruption, while manual discharge allows greater control over material flow for batch processing or when handling sensitive products that require special attention.Q: Where can the SS Bucket Elevator be installed, and what installation types are available?

A: The elevator can be installed indoors or outdoors, tailored for vertical or inclined setups as per spatial and operational requirements. Its flexible structure and customized dimensions allow integration into diverse plant layouts and processes.Q: What is the process for ordering a customized SS Bucket Elevator?

A: To purchase a custom elevator, provide details about your material type, handling requirements, space limitations, and desired specifications. The manufacturer will consult with you to design and supply an elevator that meets your specific operational needs.Q: How does the centralized lubrication system enhance the elevators performance?

A: The centralized lubrication system ensures consistent and optimal lubrication of moving parts, reducing wear and tear, minimizing maintenance frequency, and contributing to quiet operation with noise levels below 75 dB.Q: What load capacity and lifting height options are available for the SS Bucket Elevator?

A: The load capacity can be customized up to 2 tons per hour, and lifting heights can reach up to 25 meters, depending on the specific requirements and configuration chosen for your application.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bucket Elevator Category

Bucket Elevator

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Application : Industrial

Size : As per requirement

Frame Material : Stainless Steel

Industrial Rice Milling Bucket Elevator

Minimum Order Quantity : 1 Unit

Material : Mild steel

Application : Material Handling

Size : Customized

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry